UMET - Fatigue damage

Contacts :

Related groupe :

See also:

Fatigue of materials is a process in which repetitive application of loads of mechanical, thermal, magnetic origin … modifies physical, structural, mechanical properties… and the ultimate stage is the fracture of the material.

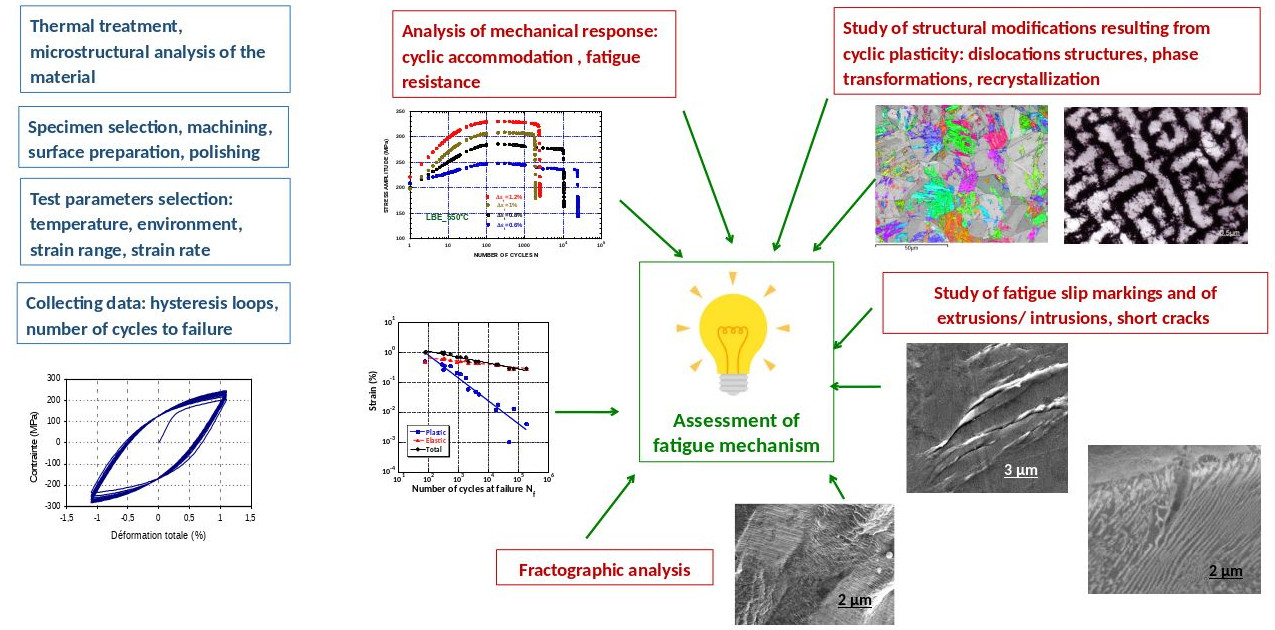

Research on fatigue of materials started when the Physical Metallurgy Lab was established. The objective of the research is to understand the response of a material to cyclic loading taking into account environment effects from deep analysis of the microstructure by advanced microscopies.

We are motivated in the understanding of cyclic accommodation phenomena and crack initiation mechanisms, and to a less extent bulk cracking mechanisms.

The research lines cover:

- dislocation structures analysis: formation, stability, damage indicator

- role of microstructure: cyclic softening-hardening phenomenon, fatigue lifetime

- crack initiation mechanisms: nucleation of intrusion, transition from intrusion to short crack

- analysis of long crack propagation modes and of fracture surfaces

Equipments >

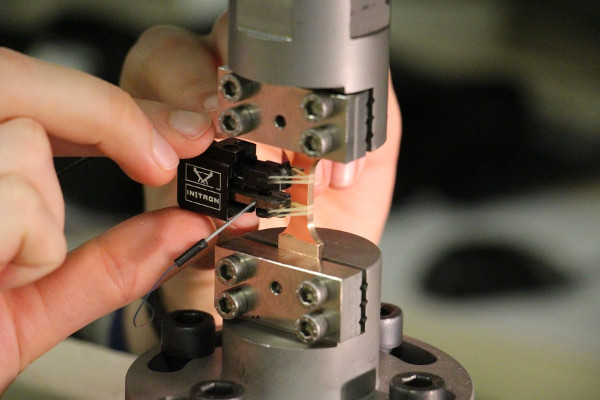

Fatigue tests are carried out under force or strain control, in tension-compression or in bending. Low cycle fatigue experiments are strain controlled tests and require therefore a servo controlled fatigue machine (hydraulic or electromechanical) and extensometers.

Our test facilities comprise:

- 4 low cycle fatige machines(250kN, 100kN, 50kN, 25kN)

- strain gage extensometers – temperature range: -196°C à + 600°C

- digital imaging correlation system (DIC)

- convection, radiation and induction furnaces

Development of specific experiments >

Fatigue tests should be conducted according to test standards (AFNOR, DIN, ASTM…). However, the material to be tested may be sometimes not available with dimensions (e.g. weak thickness) allowing testing according to the standard. And moreover, for some environments such as liquid metal, the standard does not exist.

Case-specific set ups must be designed in order to investigate the fatigue behaviour in unusual situations (aqueous environment, liquid metal, controlled atmosphere).

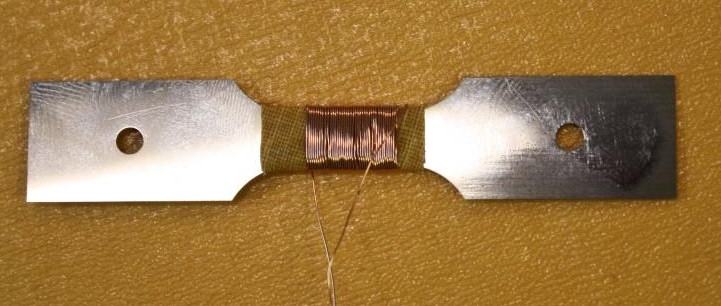

The functional properties of materials can change with the cyclic loading.Fatigue specimen must be “equipped” with component allowing the measurement of theses properties.

Methodology and experimental procedure of a research plan >

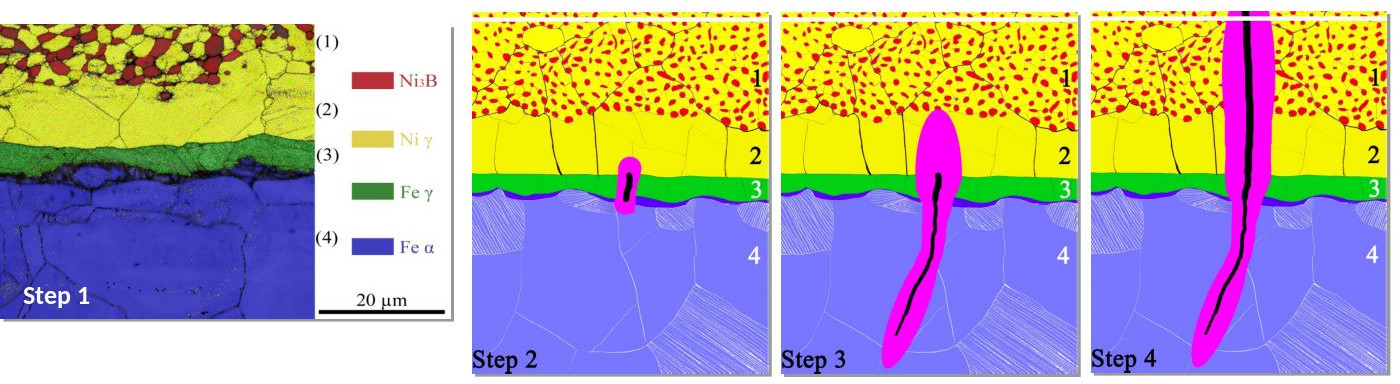

Low cycle fatigue of a Cu-Ni-Si alloy >

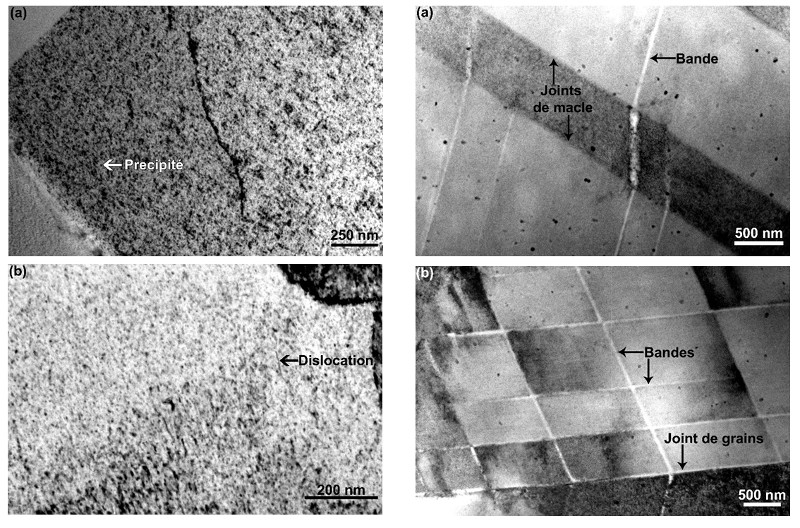

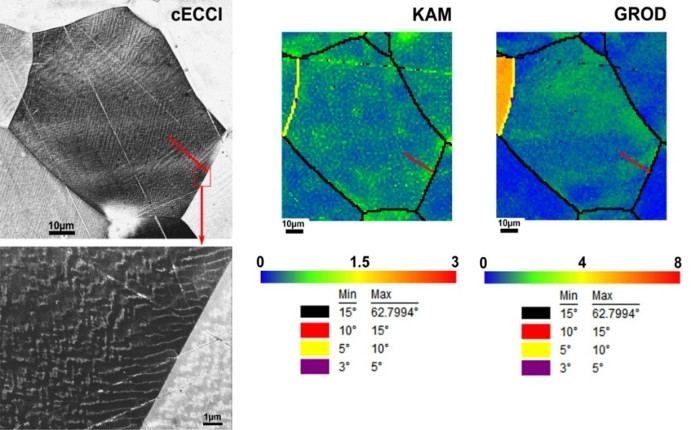

High density of dislocation debris at low Δεt Deformation « bands » in some grains and high density of dislocation debris in other grains at high Δεt

![J. Bouquerel, M. Delbove, J.-B. Vogt, Advanced processing of EBSD data to distinguish the complex microstructure evolution of a Cu-Ni-Si alloy induced by fatigue, Mater. Charact. (2018) 145 pp. 556-562 [doi: 10.1016/j.matchar.2018.09.017]](ImagesFatigue/CuNiSi-3.jpg)

J. Bouquerel, M. Delbove, J.-B. Vogt, Advanced processing of EBSD data to distinguish the complex microstructure evolution of a Cu-Ni-Si alloy induced by fatigue, Mater. Charact. (2018) 145 pp. 556-562 [doi: 10.1016/j.matchar.2018.09.017]

Thanks to the optimization of the chemical composition and heat treatment, Cu-Ni-Si alloys have a high yield strength.

With a good compromise between mechanical, thermal and electrical properties, CuNi2Si alloys with structural hardening by precipitation are used in particular for railway maintenance. They are therefore subjected to the passage of trains which generates cyclic stresses.

This study dealt with the question of maintaining mechanical properties with cyclic stresses, and with the understanding of cyclic deformation mechanism of the CuNi2Si alloy. The final outcome was to master the field of reliability of components made of this alloy.

This work was the PhD topic of Maxime DELBOVE in collaboration with the company LBI.

Low cycle fatigue of Fe3Si steel >

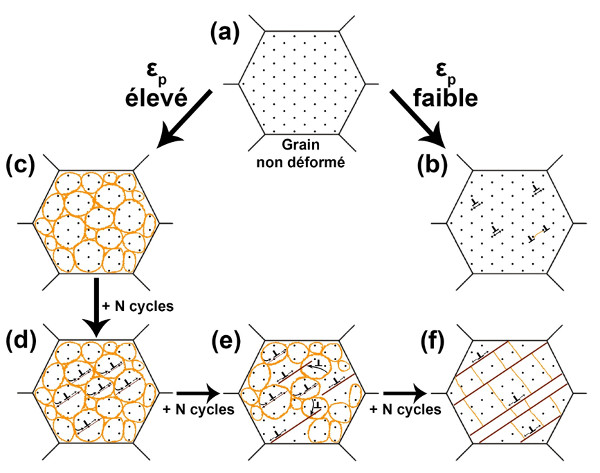

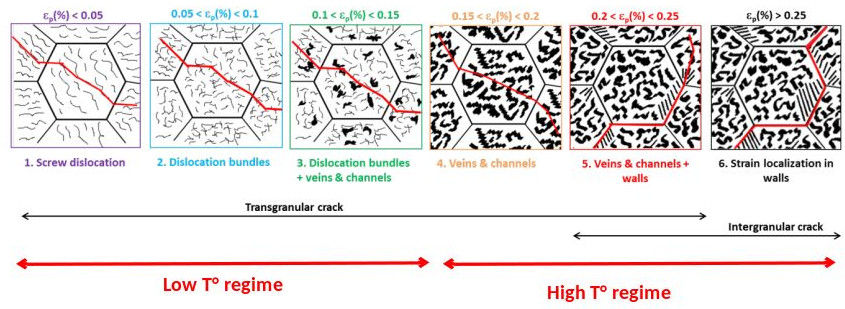

Plastic deformation localisation at micro-mesoscopic scale and consequence on crack initiation

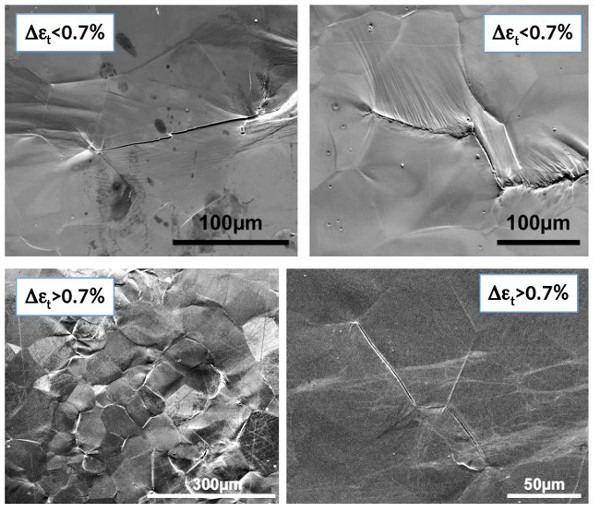

Δεt < 0.7%, transgranular crack initiation

Δεt > 0.7%, intergranular crack initiation

Deformation localisation at grain boundary and intergranular crack initiation investigated by TEM, SEM-EBSD, SEM-ECCI

Transition from transgranular to intergranular crack initiation in Fe3Si steel

- 2 regimes of strain accommodation

- Grains accommodate the strain in an individual way, dislocation glide through grains is difficult → incompatibility effects → intergranular stress → intergranular strain localisation → intergranular crack initiation

Modern motor vehicles are quipped with alternator-starters ensuring the “stop & start” function. Therefore, these machines are subjected to fatigue which may decrease their performance.

The objective of this thesis work was to study the low cycle fatigue behaviour of the Fe-3Si steel used for the rotors of new alternator-starters developed by Valeo.

The study took into account the relationship between the mechanical response and the microstructure, the fatigue mechanisms, the strain assessment at a mesoscopic scale and an optimization of the design of the rotor to improve the electromagnetic performances of the machine.

The study had to take up the challenge of carrying out tension-compression fatigue tests on 350 µm thick flat specimen.

This work was performed in the frame of the PhD thesis of Claire SCHAYES in collaboration with the Valeo company.

C. SCHAYES, J. BOUQUEREL, J.-B. VOGT, F. PALLESCHI, S. ZAEFFERER, A comparison of EBSD based strain indicators for the study of Fe-3Si steel subjected to cyclic loading Materials Characterization 115, 2016, pp. 61–70 [doi 10.1016/j.matchar.2016.03.020]

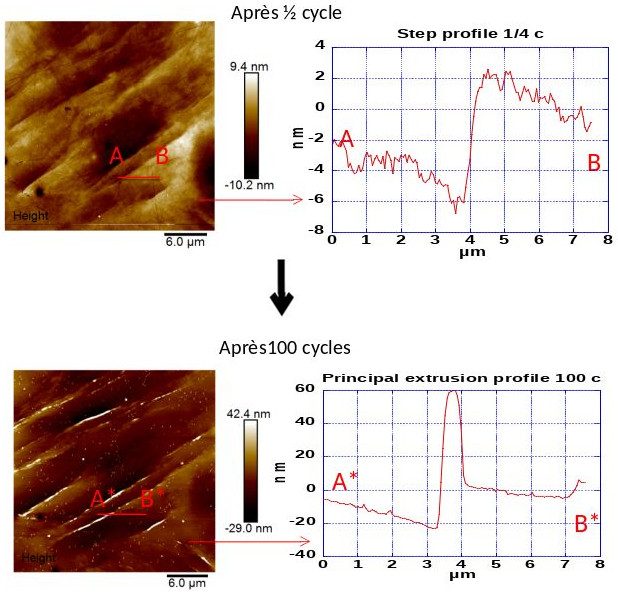

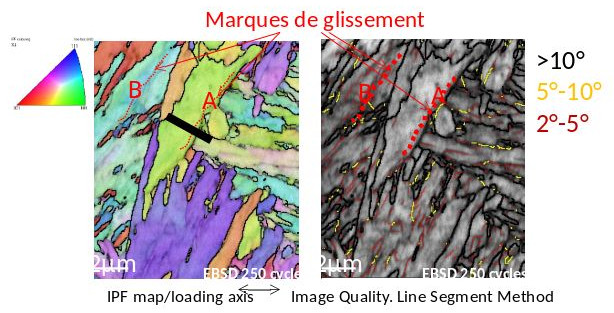

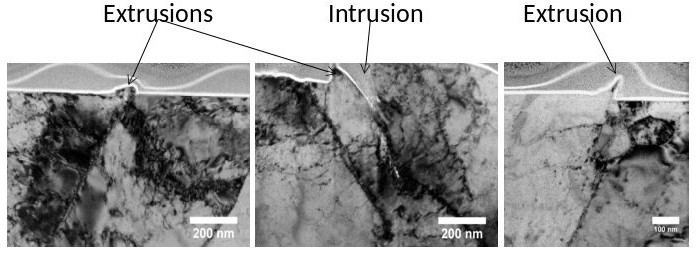

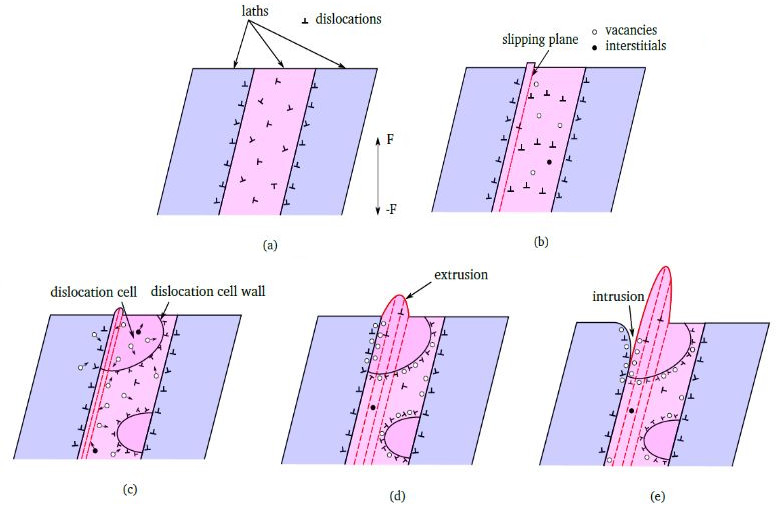

Mechanisms of intrusions nucleation and short crack initiation in a martensitic steel >

12 Cr martensitic steels are commonly used for thermal or nuclear power plant components, turbine blades, etc. They are therefore subjected to cyclic fluctuations in temperature or mechanical loading.

The specificity of martensitic steels is their complex hierarchical microstructure which consists of prior austenitic grains, packets, blocks and laths.

The objective of this work was, on the one hand, to explain the mechanism of extrusion-intrusion formation by low cycle fatigue at room temperature on the surface of a 12% chromium martensitic steel and, on the other hand , to define the role of the different interfaces of the microstructure on the formation of extrusions and intrusions.

This work was the PhD thesis topic of Gulzar SEIDAMETOVA.

G. Seidametova, J.-B. Vogt, I. Proriol Serre, The early stage of fatigue crack initiation in a 12%Cr martensitic steel International Journal of Fatigue 106, 2018, 38–48 [doi: 10.1016/j.ijfatigue.2017.09.006]

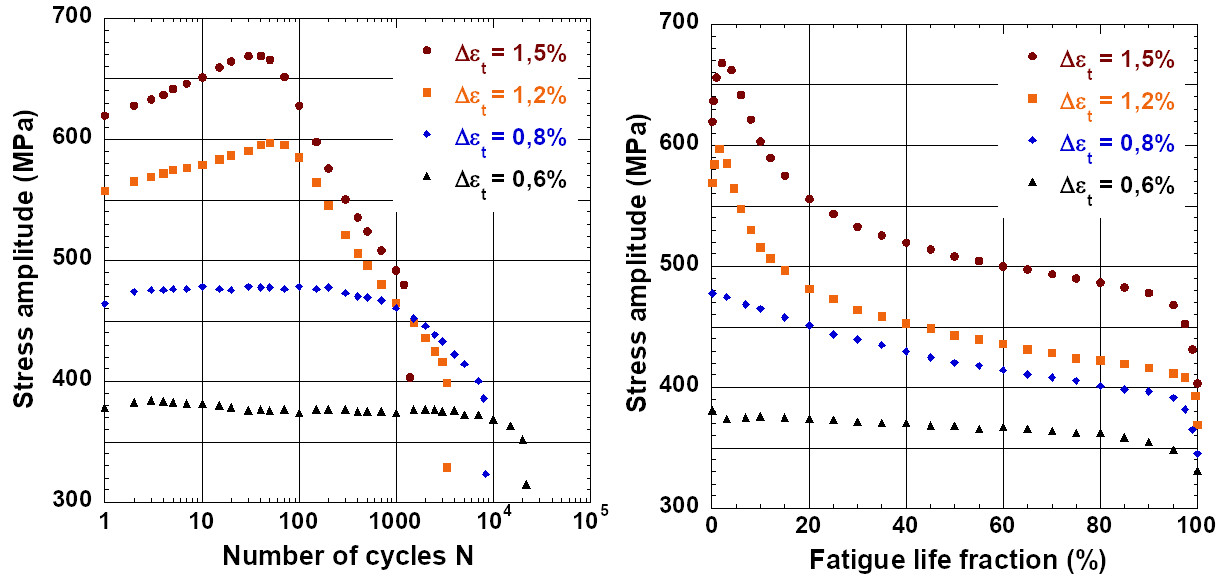

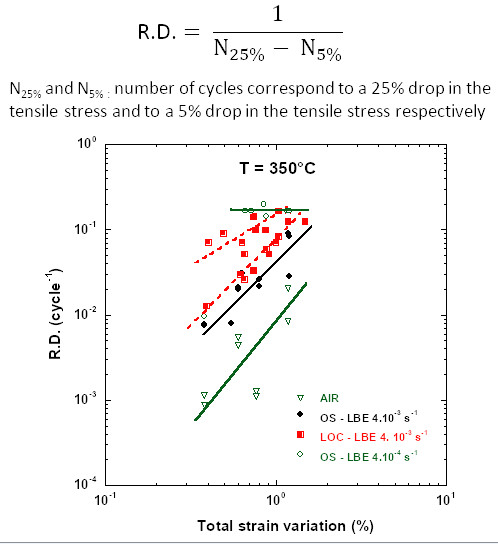

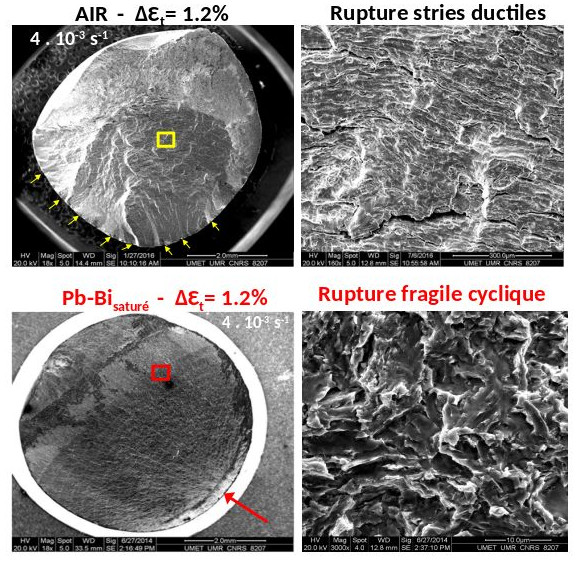

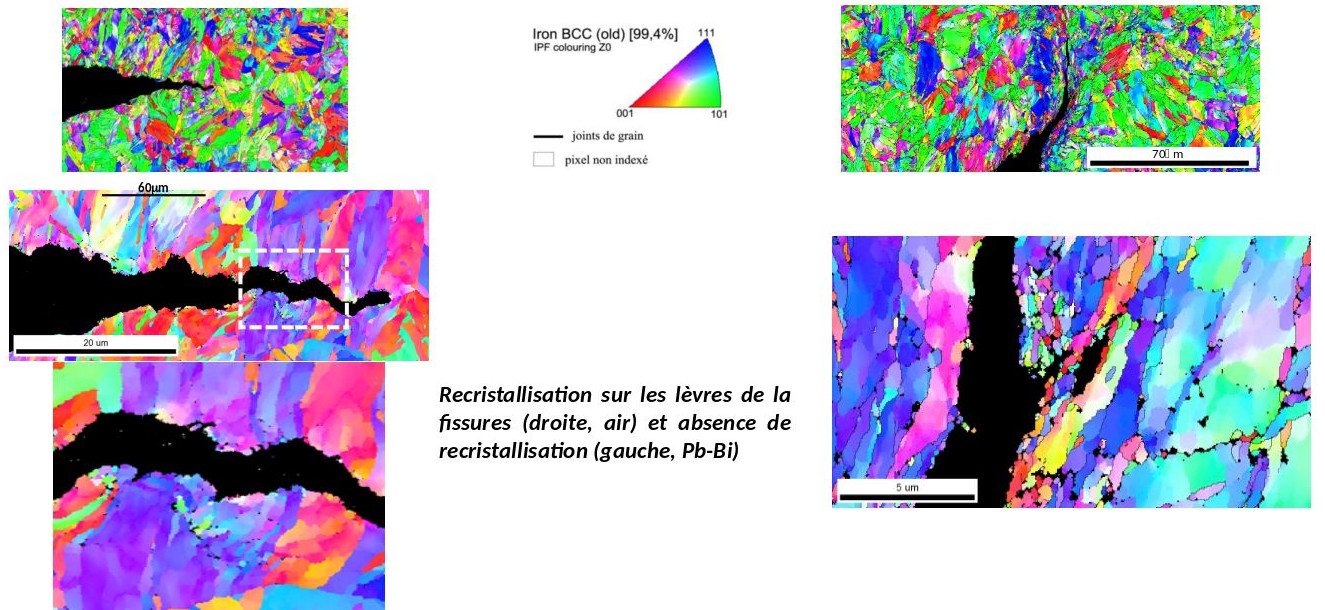

Fatigue crack propagation mechanism in a martensitic steel in presence of a liquid metal (Pb-Bi) >

One of the options for 4th generation nuclear reactors is to use lead or the Pb-Bi eutectic alloy as the heat transfer fluid.

The objective of this study was to achieve a better understanding of the mechanical behaviour and damage mechanisms of low cycle fatigue of the martensitic steel T91 at 350 °C in the presence of the liquid Pb-Bi eutectic. The effect of the dissolved oxygen content in the liquid metal, the test temperature, the strain rate and the signal waveform was analysed.

This research was carried out in the frame of the PhD thesis of Carla CARLE within the framework of the European project MatISSE.

Stability of fatigue cracks at 350°C in air and in liquid metal in T91 martensitic steel, J.-B. Vogt, J. Bouquerel, C. Carle, I. Proriol Serre, Int. J. Fatigue 130, 2020, 105265 [doi: 10.1016/j.ijfatigue.2019.105265

See also: additional slide on the mechanism of fatigue crack advance in T91 steel at 350°C in air and in Lead-Bismuth Eutectic (LBE).

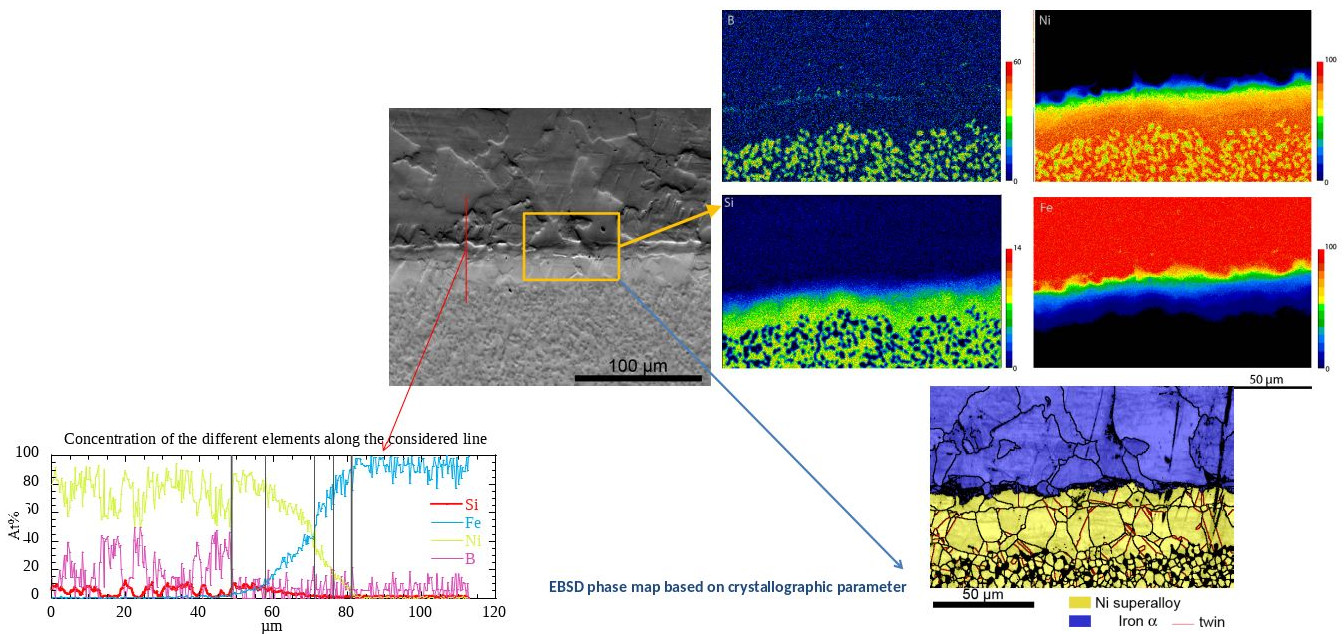

Mechanisms of fatigue cracking in a bi-metallic material (steel –Ni3B) >

The manufacture of glass items sometimes requires the use of bi-metallic glassware moulds. The conditions of use mean that they are subjected to cyclic thermal stresses which can generate cracks in the thick coating.

This work aimed to identify the sources of damage and to understand the mechanisms of crack initiation in a bi-metallic mould, here constituted by a ferrito-perlitic steel substrate covered with a thick coating of boron nitride.The performance of this bi-metallic mould was then compared to that of a monolithic one to estimate the benefits.

This work was carried out in the frame of the PhD thesis of Hélène BULTEL in collaboration with the company ARC International.

Leader and contact: Jean-Bernard VOGT (PR)

Contributors: Jérémie BOUQUEREL (MCF), Ingrid PRORIOL SERRE (CR), Jocelyn GOLEK (IE), Damien CRETON (Tech.)

The gained knowledge in this research field have been shared with our PhD collaborators:

Mahira ARAÚJO, Gulzar SEIDAMETOVA, Maxime DELBOVE, Carla CARLE, Claire SCHAYES, Abderrazak DAOUD, Floriane LEAUX, Hélène BULTEL, Daniel SALAZAR, Stéphanie BROCHET, Arnaud VERLEENE, José Balbino LEON SOSA Karen MASSOL, Sylvie ARGILLIER, Olivier BOUSSAC, Catherine BIGEON