Physical Metallurgy and Materials Engineering

- Home

- Team directory

- Publications

- Communications

- PhD thesis

- Collaboration network

- Former group members

Equipements

- General database

- Elaboration:

- Characterization:

Research themes

Ongoing projects

- Projet COMASYS

- Interreg SAFE

- ANR JCJC RESSET

- ANR MustImplant - Multiscale Smart Texturing of Medical Implants

- PIA ISAC - Innovative System for Actinides Conversion

Completed projects

- Projet européen INNUMAT

- ANR GauguIn

- Interreg SOCORRO2

- Interreg Allihentrop - Synthèse et mise en œuvre de revêtements à base d'ALLIages à Haute ENTROPie

- European project H2020 : GEMMA for GEneration iv Materials MAturity

- Interreg_transport - Réseau TRANSfrontalier pour le développement de revêtements sol-gel POReux sur métaux pour applications Tribologiques

Documents

- Thermodynamique et défauts ponctuels (ADPI)

UMET - Physical Metallurgy and Materials Engineering

Team leader: Ingrid PRORIOL SERREMembers

The main research topics on which the team is working are related to physical metallurgy, mechanical metallurgy and numerical metallurgy.

The team develops and investigates microstructures in order to understand their mechanisms of formation and evolution: during and after elaboration, in aggressive environment and under mechanical loading.

Complementary approaches are considered:

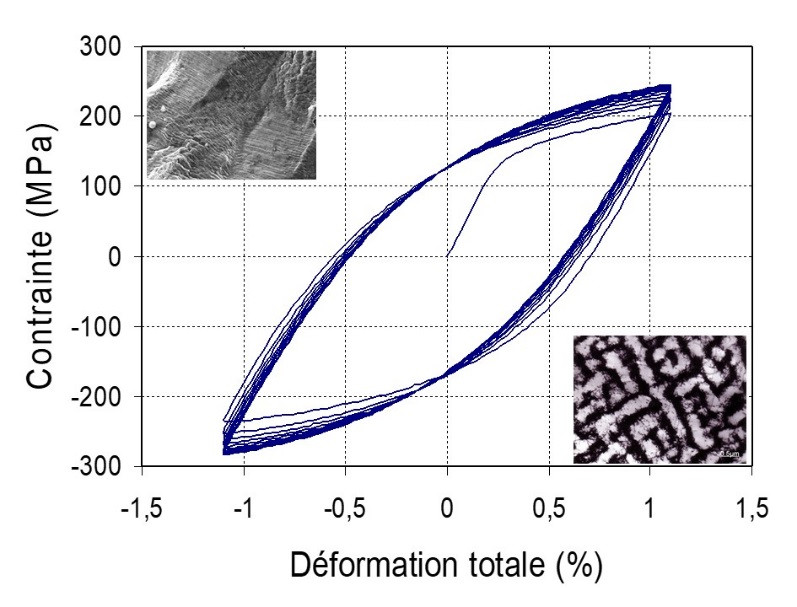

- The study and understanding of mechanical properties (monotonic, cyclic) of metallic alloys, especially by taking into account the effect of environment (for instance in liquid metal).

- The understanding of the link between microstructures and properties of use.

- The development and implementation of numerical methods to explain and predict microstructures observed using both atomic and continuous approaches.

The tools and know-how used and / or developed in the laboratory are:

- for elaboration: mechanical alloying, powder metallurgy, melting by inductive heating,

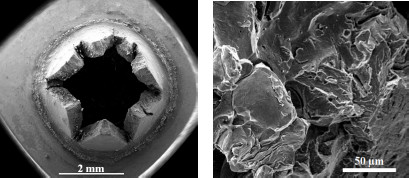

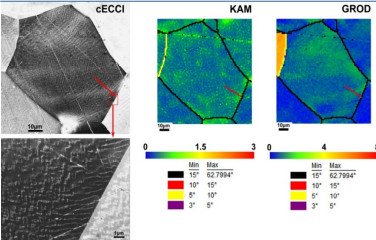

- for characterization: monotonic tests (i.e. tensile, compression, SPT, bending on standard and miniaturized specimens) and low cycle fatigue in controlled environments (in liquid metal, high temperature …), instrumented micro-indentation, Mössbauer spectroscopy, electron microscopy (SEM, TEM), electron diffractions (precession, EBSD, TKD, ASTAR), atomic force microscopy,

- for modelling: ab initio calculations, empirical potentials, cluster Hamiltonians, molecular dynamics, cluster dynamics, Monte Carlo, mean field methods (CVM), kinetic Monte Carlo, phase field.

The research axes of the team are centered around 3 main themes:

Understanding of damage mechanisms >

![Solute binding energy with a loop containing 37 self-interstitials in α Fe: DFT (density functional theory) calculations. C. Domain, C. Becquart, Journal of Nuclear Materials 499, 582-594 (2018), [doi: 10.1016/j.jnucmat.2017.10.070]](Illustrations/energieLiaison.jpg)

Solute binding energy with a <111> loop containing 37 self-interstitials in α Fe: DFT (density functional theory) calculations. C. Domain, C. Becquart, Journal of Nuclear Materials 499, 582-594 (2018), [doi: 10.1016/j.jnucmat.2017.10.070]

The scientific objectives are to understand the mechanisms of damage of metallic materials. Fatigue damage and cyclic plasticity of metallic alloys are one of the topics initiated at the creation of the laboratory and which contributed to its development and recognition.

An important activity is conducted within the framework of nuclear structural materials. The origin of the damage being radiative, mechanical and corrosive, it is necessary to develop original experimental devices and develop simulation tools. This activity is conducted through two main research areas: liquid metal embrittlement and simulations of microstructures under irradiation.

Galvanization, also a historical topic of the laboratory, is studied through the degradation of metallic materials during their immersion in liquid alloys such as liquid zinc and liquid aluminum.

Design of high performance metallic materials >

The scientific objectives targeted in this theme are to design, develop, characterize and test materials or coatings with high performance in terms of their mechanical behavior, heat transfer or resistance to aggressive environments.

This theme is divided into 3 topics:

- Metal matrix composites

- Assemblies and surface treatments

- Advanced metallurgy of alloys out of or at equilibrium

Methodological developments in metallurgy >

An important part of the activities of the MPGM team consists in developing new experimental and numerical methods to study phase transformations and microstructure evolutions in the context of topics “Understanding damage mechanisms” and “Design of high performance metallic materials”.

On the one hand, we develop numerical methods at the atomic scale to evaluate the energy contributions accompanying the appearance of a new phase or a microstructural defect in a metal matrix. These different quantities can be used as input data for mesoscopic models such as kinetic Monte Carlo object or phase field. Methodological developments are regularly made to improve these approaches and to incorporate new phenomena.

On the other hand we use and improve, within the Chevreul federation, electron diffraction-based techniques at various scales, going from the micro-level to the meso-level (microscopic: TEM (ASTAR) & MEB (TKD), mesoscopic: SEM-EBSD and SEM-ECCI). We also develop methods based on the post-processing of EBSD data (and more commonly Orientation Imaging Microscopy data) to identify and quantify deformation fields (elastic and plastic) via a precise measurement of local disorientation.